“Pumping and Hydraulics’ Solutions for Irrigation and Water Supply”

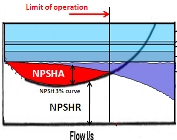

Week 2: NPSH & Pump Suctions

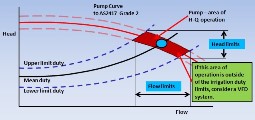

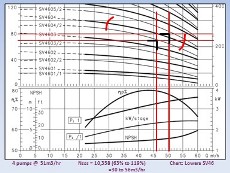

Single pump selection can become quite complex Graph: R Welke

Week 6: Commissioning

A range of Tallemenco designed software will be free issued to each student, enabling irrigation pump selection with various pipe types, diameters and friction values (C Values) plus pump speed and impeller trimming software. In addition, students will have access to Tallemenco's latest web based software, Hydropz (Hydraulic Optimisation).

Week 1: Pipelines & System Curves

Pipeline design may contain so many variables that pump duties become wide targets.

Graph: R Welke

Graph: R Welke

ABN 92 105 345 506

Advanced Pump System Design - Online Training

(formerly "Advanced Pump Station Design")

MODULE SUMMARY

(formerly "Advanced Pump Station Design")

MODULE SUMMARY

American Society of Irrigation Consultants

Full Professional Member 2011

Full Professional Member 2011

Pipelines & System Curves

NPSH & Pump Suctions

Pump Selection

Pump Station Design

Pump Station Design

Commissioning

NPSH & Pump Suctions

Pump Selection

Pump Station Design

Pump Station Design

Commissioning

Week 1

Week 2

Week 3

Week 4

Week 5

Week 6

Week 2

Week 3

Week 4

Week 5

Week 6

Pipe friction - causes, components, hydraulic

gradients, friction charts

Calculating friction: DW and H&W, charts

Measuring friction on site

Hydraulic optimisation: calculating,

case study, software

Pipelaying: principles, precautions

Pipe ageing: effects, compensating, designing

Pigging pipelines: case studies

System Curves: single flow, multiple lifts,

multiple flows and outputs

Tutorial, Pipe size selection software

gradients, friction charts

Calculating friction: DW and H&W, charts

Measuring friction on site

Hydraulic optimisation: calculating,

case study, software

Pipelaying: principles, precautions

Pipe ageing: effects, compensating, designing

Pigging pipelines: case studies

System Curves: single flow, multiple lifts,

multiple flows and outputs

Tutorial, Pipe size selection software

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

NPSH: definitions, measurement, suction lift,

flooded suction, NPSHr and NPSHa,

vertical turbines (special case)

Pump suction: Rules, screens, priming, vortexing

Case histories:

1) blocked screen

2) submersible in wet well

3) end suction in wet well

4) end suction on pallet

5) remote suction screening

6) algae screening

7) vacuum priming

8) level rise and fall

9) suction screening

10) impeller cavitation

11) split suctions

Tutorial, NPSH software

flooded suction, NPSHr and NPSHa,

vertical turbines (special case)

Pump suction: Rules, screens, priming, vortexing

Case histories:

1) blocked screen

2) submersible in wet well

3) end suction in wet well

4) end suction on pallet

5) remote suction screening

6) algae screening

7) vacuum priming

8) level rise and fall

9) suction screening

10) impeller cavitation

11) split suctions

Tutorial, NPSH software

Last Updated

Feb 25th 2018

Feb 25th 2018

Week 5: Pump Station Design, cont

Electrical

motor starters and controllers,

single pump control

multiple pump control, vert multistage

multiple pump control, end suction

tank level monitoring - multi-level

tank level monitoring - pressure transducer

suction pressure control

wiring diagrams

control panel weather protection: IP rating

Accessories:

filters, types, back-flush operation

isolation valves, check valves

hydraulic valves,

flowmeters,

air tanks, dosing,

vacuum priming

WH&S

ladders

access & working space

first aid, eye wash

danger signage

hazardous chemicals

labeling

Documentation

communications

project stages

conceptual design

engineered design

specifications

Maintenance Manuals

Tutorial

motor starters and controllers,

single pump control

multiple pump control, vert multistage

multiple pump control, end suction

tank level monitoring - multi-level

tank level monitoring - pressure transducer

suction pressure control

wiring diagrams

control panel weather protection: IP rating

Accessories:

filters, types, back-flush operation

isolation valves, check valves

hydraulic valves,

flowmeters,

air tanks, dosing,

vacuum priming

WH&S

ladders

access & working space

first aid, eye wash

danger signage

hazardous chemicals

labeling

Documentation

communications

project stages

conceptual design

engineered design

specifications

Maintenance Manuals

Tutorial

*

*

*

*

*

*

*

*

*

Tallemenco Pty Ltd,

Windsor Gardens, SOUTH AUSTRALIA, 5086.

ABN: 92 105 345 506

Phone: Mobile 0414 492 256 Int'l: Cell +61 414 492 256 Skype: robwelke

Windsor Gardens, SOUTH AUSTRALIA, 5086.

ABN: 92 105 345 506

Phone: Mobile 0414 492 256 Int'l: Cell +61 414 492 256 Skype: robwelke

Week 3: Pump Selection

Motor starters and speed control

NPSH: pumps with different speeds

Irrigation duty selection:

single flow

multiple flows

multiple flows and heads

Best Efficiency Point (BEP)

Limits of pump duty

(ULD, LLD, ULSO, LLSO)

Filter backflush

media

disc

screen

Pump guarantee limits:

testing, pump selection

Pump materials and corrosion

VFD's

how do they work

limitations

configurations

Pump selection:

single pump

multiple pump

multiple pumps, multiple heads

Tutorial, Pump selection software

NPSH: pumps with different speeds

Irrigation duty selection:

single flow

multiple flows

multiple flows and heads

Best Efficiency Point (BEP)

Limits of pump duty

(ULD, LLD, ULSO, LLSO)

Filter backflush

media

disc

screen

Pump guarantee limits:

testing, pump selection

Pump materials and corrosion

VFD's

how do they work

limitations

configurations

Pump selection:

single pump

multiple pump

multiple pumps, multiple heads

Tutorial, Pump selection software

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

Week 4: Pump Station Design

Pre-start checks, suction lift and flooded suction

Start-up procedures, suction lift and flooded suction

Commissioning:

test pumps

test no-flow switch

test PSV

test filter backflush

vacuum switch

pressure tank

tank level control

On site Training

Maintenance

Trouble shooting

pump testing software

Start-up procedures, suction lift and flooded suction

Commissioning:

test pumps

test no-flow switch

test PSV

test filter backflush

vacuum switch

pressure tank

tank level control

On site Training

Maintenance

Trouble shooting

pump testing software

*

*

*

*

*

*

*

*

*

*

*

*

*

Power supply: electric supply, upgrades,

diesel motors, solar pumping systems

Building designs:

open air,

closed structure,

dry wells,

Council approvals, DA's

Pipework

diameters, materials, flexible joints REJ's,

RLRJ's, support and thrust,

flange standards and codes,

fasteners materials and corrosion,

colour codes, pigging pipework

Tutorial

diesel motors, solar pumping systems

Building designs:

open air,

closed structure,

dry wells,

Council approvals, DA's

Pipework

diameters, materials, flexible joints REJ's,

RLRJ's, support and thrust,

flange standards and codes,

fasteners materials and corrosion,

colour codes, pigging pipework

Tutorial

*

*

*

*

*

*

*

NPSH limits the operation of pumps, and presents real challenges for pump selection.

Graph: R Welke

Graph: R Welke

Multiple pump selection with multiple duties Graph: R Welke

Pipework design is crucial to efficient performance Photo: R Welke

Multiple pump control is very specialised. Photo: R Welke

Ladder design is critical to safety.

Photo: R Welke

Photo: R Welke

Testing pumps is an important step in the commissioning process

Photo: R Welke

Photo: R Welke

Solar array for sun power

This 6 week course explores advanced concepts in irrigation pipeline and pump system design.

These concepts are demonstrated with specialised software and numerous case studies.

This course has been accredited by Irrigation Australia for PROFESSIONAL DEVELOPMENT.

These concepts are demonstrated with specialised software and numerous case studies.

This course has been accredited by Irrigation Australia for PROFESSIONAL DEVELOPMENT.