“Pumping and Hydraulics’ Solutions for Irrigation and Water Supply”

Pumping Station & Pipeline Design

Pump Stations

We have all heard that "oils aint oils". Well, in the same way, pumping stations aren’t just pumping stations. Each one is a unique creation.

Tallemenco designs pumping stations using a 132 point planner, devised “in house” from Rob's 50 + years of experience of pumping station design, installation, operation and maintenance.

We have all heard that "oils aint oils". Well, in the same way, pumping stations aren’t just pumping stations. Each one is a unique creation.

Tallemenco designs pumping stations using a 132 point planner, devised “in house” from Rob's 50 + years of experience of pumping station design, installation, operation and maintenance.

Fit for Purpose

Tallemenco designs are “fit for purpose”, that is to say, the most suitable type of pumps, appropriate pipework size, flow metering and filtration, use of stainless steel or coated metals, all in a maintainable position inside of the building or area that will house them.

Corrosion prevention also gets major consideration in our designs.

Tallemenco designs are “fit for purpose”, that is to say, the most suitable type of pumps, appropriate pipework size, flow metering and filtration, use of stainless steel or coated metals, all in a maintainable position inside of the building or area that will house them.

Corrosion prevention also gets major consideration in our designs.

Tallemenco Manager, Rob Welke, has designed over 120 pumping stations up to 525kW over the last 3 decades and physically built, installed and commissioned at least half of them, all over Australia and SE Asia.

Commissioning large Pump System that Rob designed and built for Tea Tree Oil plantation, Nth Qld when with Hydrotech 1998 Photo, R Welke

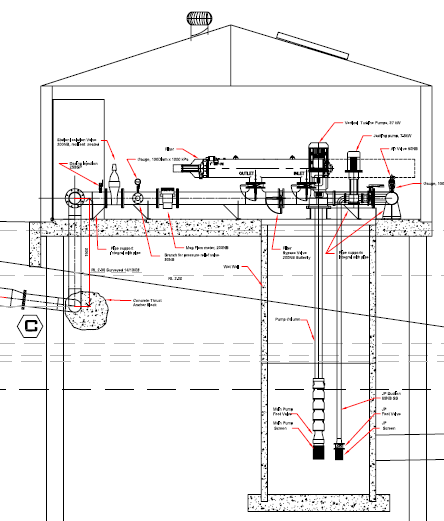

CAD drawing of Pump Station, Hope Island Resort, SE Qld. Dwg R Welke

Vacuum priming system for a pump suction, designed and built by Rob (mechanical) and son Clinton (PLC logic) at Hydrotech Aust. Photo, R Welke

All designs come complete with working drawings, specifications and Bill of Material (or Schedule of Quantities) to enable the client to shop around for contract installers and component suppliers.

Whilst Rob no longer builds pump stations, his extensive knowledge ensures that your project won’t be a trial design or an untried experiment and will therefore save you money in the long run!

Contact Tallemenco for a quote to design and Project Manage your pumping station and save you money in the long run!

Whilst Rob no longer builds pump stations, his extensive knowledge ensures that your project won’t be a trial design or an untried experiment and will therefore save you money in the long run!

Contact Tallemenco for a quote to design and Project Manage your pumping station and save you money in the long run!

Some of the 120+ Pump Stations designed and built:

Golf Pump Systems

Hope Island Resort GC, QLD (74kW) 2 vertical turbines designed only

Royal Adelaide GC, SA (61 kW) 4 vert multistage inst/com

Kooyonga GC, SA (103 kW) 4 vert multistage inst/com

Glenelg GC, SA (77 kW) 4 vert multistage inst/com

Wirrina Cove Resort GC, SA (175 kW) 6 vert multistage, 4 end suctions inst/com

Royal Canberra GC, ACT (132 kW) 6 vert multistage

Woodend GC, VIC (52 kW) 4 vert multistage

Tamworth GC, NSW (54 kW) 4 vert multistage

Canowindra GC NSW (52kW) 4 vert multistage

Tallwoods GC NSW (153kW) 4 horiz submersibles inst/com

Dumbea GC, New Caledonia (45 kW) 4 horiz submersibles com

Sentul Hill GC, Indonesia (90 kW) 3 vert submersibles

Turf Pump Systems

Sanctuary Cove Resort, QLD (50 kW) 3 x vert submersibles com

Brisbane Airport Corporation QLD (30 kW) 2 x vert multistage designed/com

Ipswich Blue Gum Reserve QLD (7.5 kW) 1 x submersible in can designed

Horticulture Pump Systems

Governor Gen’s Residence, ACT (36 kW) 4 vert multistage inst/com

Australian Vintage, Loxton, SA (525 kW) 3 horiz split casing inst/com

Orlando, Langhorne Creek, SA (330 kW) 3 end suctions inst/com

Vineyards, Molong, NSW (131 kW) 3 end suctions com

Tea Tree Plantations, Nth Qld (315 kW) 5 end suctions com

Mildara Blass, Lake Alexandrina SA (56 kW) 1 end suction, 1 vert multistage com

Southcorp Vines, Glen Lofty, VIC (48 kW) 1 end suction, 1 vert multistage inst/com

Thomsons Vines, Waikerie, SA (500 kW) 3 end suctions inst/com

Kirribilly Vineyards, Clare SA (200 kW) 6 vert multistage inst/com

Golf Pump Systems

Hope Island Resort GC, QLD (74kW) 2 vertical turbines designed only

Royal Adelaide GC, SA (61 kW) 4 vert multistage inst/com

Kooyonga GC, SA (103 kW) 4 vert multistage inst/com

Glenelg GC, SA (77 kW) 4 vert multistage inst/com

Wirrina Cove Resort GC, SA (175 kW) 6 vert multistage, 4 end suctions inst/com

Royal Canberra GC, ACT (132 kW) 6 vert multistage

Woodend GC, VIC (52 kW) 4 vert multistage

Tamworth GC, NSW (54 kW) 4 vert multistage

Canowindra GC NSW (52kW) 4 vert multistage

Tallwoods GC NSW (153kW) 4 horiz submersibles inst/com

Dumbea GC, New Caledonia (45 kW) 4 horiz submersibles com

Sentul Hill GC, Indonesia (90 kW) 3 vert submersibles

Turf Pump Systems

Sanctuary Cove Resort, QLD (50 kW) 3 x vert submersibles com

Brisbane Airport Corporation QLD (30 kW) 2 x vert multistage designed/com

Ipswich Blue Gum Reserve QLD (7.5 kW) 1 x submersible in can designed

Horticulture Pump Systems

Governor Gen’s Residence, ACT (36 kW) 4 vert multistage inst/com

Australian Vintage, Loxton, SA (525 kW) 3 horiz split casing inst/com

Orlando, Langhorne Creek, SA (330 kW) 3 end suctions inst/com

Vineyards, Molong, NSW (131 kW) 3 end suctions com

Tea Tree Plantations, Nth Qld (315 kW) 5 end suctions com

Mildara Blass, Lake Alexandrina SA (56 kW) 1 end suction, 1 vert multistage com

Southcorp Vines, Glen Lofty, VIC (48 kW) 1 end suction, 1 vert multistage inst/com

Thomsons Vines, Waikerie, SA (500 kW) 3 end suctions inst/com

Kirribilly Vineyards, Clare SA (200 kW) 6 vert multistage inst/com

Pipeline Design

Tallemenco uses EPANet for pipeline design. This is water pipeline specific software which assists in pipe diameter selection given required flows and pipeline friction values, from which Rob's experience from pipeline friction testing enables realistic inputs to its designs.

EPANet enables real pump curves to be included in the design, with a variety of hydraulic valves. The end design can be test run before it gets to the ground.

From Rob's experience in pipeline design and project management, all of the physical requirements for pipeline installation, such as thrusting, bedding are covered in Tallemenco's designs.

Contact Tallemenco for your pumping station and pipeline design requirements.

Tallemenco uses EPANet for pipeline design. This is water pipeline specific software which assists in pipe diameter selection given required flows and pipeline friction values, from which Rob's experience from pipeline friction testing enables realistic inputs to its designs.

EPANet enables real pump curves to be included in the design, with a variety of hydraulic valves. The end design can be test run before it gets to the ground.

From Rob's experience in pipeline design and project management, all of the physical requirements for pipeline installation, such as thrusting, bedding are covered in Tallemenco's designs.

Contact Tallemenco for your pumping station and pipeline design requirements.

EPANet software enables pump curve, pipeline friction and valve losses to be included in design calculations so that a pumping/pipeline system can be "test run" before installation.

ABN 92 105 345 506

Last Update

Jan 6th, 2021

Jan 6th, 2021

Tallemenco Pty Ltd, Windsor Gardens, SOUTH AUSTRALIA, 5087.

ABN: 92 105 345 506

Mobile 0414 492 256

Intn'l: Cell +61 414 492 256

Skype: robwelke

ABN: 92 105 345 506

Mobile 0414 492 256

Intn'l: Cell +61 414 492 256

Skype: robwelke

TALLEMENCO NO LONGER DESIGNS PUMPING STATIONS