“Pumping and Hydraulics’ Solutions for Irrigation and Water Supply”

Pump Testing (on-site)

The purpose of site testing pumps is to establish a pump's present performance to enable that to be compared with previous tests to establish reduced flow output and increased running costs. Testing pumps involves measuring the head (Hm), flow (l/s) and power (EkW) characteristics of a pump. Pump speed (rpm) and line voltage (VAC) may also be measured.

Works Tests

There are well defined guidelines for testing pumps, as in AS ISO 9906 2018, which defines several classes of accuracy for pump test results. Typically, this standard would apply to Works Testing of pumps before they are delivered to the end client, or a well designed commercial pump test bay.

There are well defined guidelines for testing pumps, as in AS ISO 9906 2018, which defines several classes of accuracy for pump test results. Typically, this standard would apply to Works Testing of pumps before they are delivered to the end client, or a well designed commercial pump test bay.

Site Tests

However, once pumps are installed on site, a quite different situation applies. Rarely do the pressure tapping points comply with any standard, power measurement almost invariably includes local switchboard consumption and flowmetering is usually anything but to AS ISO 9906 2018 requirements. If the pump is diesel engine driven, it is usually impractical to establish power input.

However, once pumps are installed on site, a quite different situation applies. Rarely do the pressure tapping points comply with any standard, power measurement almost invariably includes local switchboard consumption and flowmetering is usually anything but to AS ISO 9906 2018 requirements. If the pump is diesel engine driven, it is usually impractical to establish power input.

Site testing usually requires a number of allowances, such as velocity head, gauge elevation, pipe losses and power corrections. Repeatability is the key to all test results. However, even given these allowances, Rob has rarely seen a site commissioning test result ever emulate a works test result or a manufacturer's standard pump curve!

Testing pumps is Tallemenco's core strength. Photo: R Welke

Benchmark Performance

Therefore, all site tests must adopt their own testing "standards", which are of course unique to each site and used for each subsequent test to obtain repeatability. The first test at site then becomes the Benchmark Performance, from which all subsequent test result comparisons, such as reduced flow output and increased power, are derived.

If a site commissioning test result is not available, then the first field test becomes the benchmark test.

Therefore, all site tests must adopt their own testing "standards", which are of course unique to each site and used for each subsequent test to obtain repeatability. The first test at site then becomes the Benchmark Performance, from which all subsequent test result comparisons, such as reduced flow output and increased power, are derived.

If a site commissioning test result is not available, then the first field test becomes the benchmark test.

Unfortunately, if the pump has been in service for some years, this test result will not necessarily be indicative of the best performance of that pump.

However, the test result will provide useful data from which to draw conclusions for potential power cost savings and additional pumped output if the pump was overhauled.

Once the pump has been overhauled, that is then the correct time to site test the pump to establish its benchmark performance.

However, the test result will provide useful data from which to draw conclusions for potential power cost savings and additional pumped output if the pump was overhauled.

Once the pump has been overhauled, that is then the correct time to site test the pump to establish its benchmark performance.

All of Tallemenco’s pump tests come complete with an economic analysis. This indicates to the client the increase in annualized electricity costs (or diesel fuel costs) due to reduced pumping efficiency, how much energy cost savings will be possible with a pump overhaul, and the likely increased pumping capacity. This in turn will assist the client to establish pump overhaul economics and schedules.

Rob has produced a pump data chart which enables users to quickly derive pumping costs ($/ML) from given head (m), assumed pump efficiency and electrical cost (c/kWh).

Contact Tallemenco for a quote to site test your pumps, complete with economic analysis!

Rob has produced a pump data chart which enables users to quickly derive pumping costs ($/ML) from given head (m), assumed pump efficiency and electrical cost (c/kWh).

Contact Tallemenco for a quote to site test your pumps, complete with economic analysis!

Testing experience

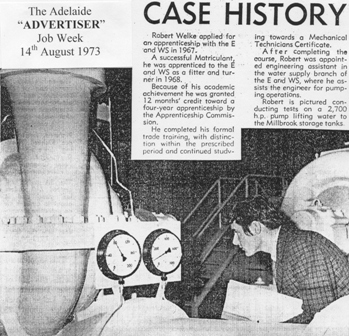

During the 1970’s to early 1990’s, Rob conducted over 1000 pump tests on pumps ranging from 22kW to 5,000 kW. These tests were carried out on SA Water pumps both for potable water distribution and irrigation pumps on the River Murray in South Australia (see photo below).

In addition, Rob witnessed and approved Works Tests on new pumps at Manufacturers Works such as Thompson, Kelly and Lewis (now collectively TKL) and Harland.

Obtaining accurate pump test results on site involves knowing the ideal pressure tapping points locations, how to read electricity meters and what local consumption to allow for, but most importantly, knowing how accurate the site flow meter is likely to be.

During the 1970’s to early 1990’s, Rob conducted over 1000 pump tests on pumps ranging from 22kW to 5,000 kW. These tests were carried out on SA Water pumps both for potable water distribution and irrigation pumps on the River Murray in South Australia (see photo below).

In addition, Rob witnessed and approved Works Tests on new pumps at Manufacturers Works such as Thompson, Kelly and Lewis (now collectively TKL) and Harland.

Obtaining accurate pump test results on site involves knowing the ideal pressure tapping points locations, how to read electricity meters and what local consumption to allow for, but most importantly, knowing how accurate the site flow meter is likely to be.

Testing a 600l/s x 130m, 1000kW TKL SCO pump,Millbrook PS, SA. Photo: Adelaide Advertiser 1973

On-site pump testing accuracy is 90% conditional on site flow metering accuracy. As Rob has had extensive experience in flowmeter evaluations, he is well equipped to evaluate this and all other parameters required to achieve the best site test accuracy.

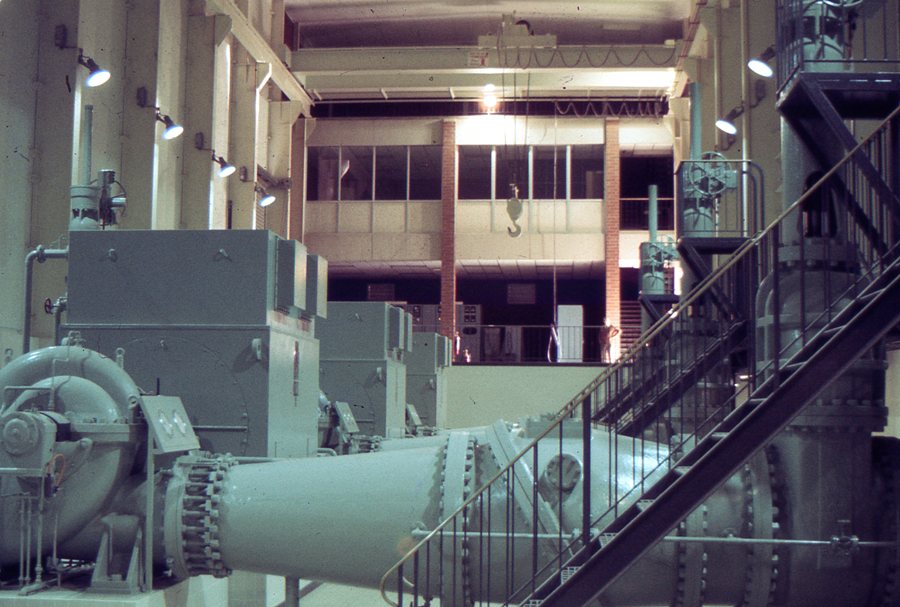

The pumps in the Murray Bridge-Onkaparinga No3 Pumping Station (left) were amoungst the largest pumps Rob has tested. These pumps, double suction horizontal split casing K&L's, are all 316SS, including the cast pump bodies, and stand about 1.5m tall. The 5670 kW motors drive these pumps to provide the required 201metres head at 1970 litres per second.

The pumps in the Murray Bridge-Onkaparinga No3 Pumping Station (left) were amoungst the largest pumps Rob has tested. These pumps, double suction horizontal split casing K&L's, are all 316SS, including the cast pump bodies, and stand about 1.5m tall. The 5670 kW motors drive these pumps to provide the required 201metres head at 1970 litres per second.

Murray Bridge-Onkaparinga No3 PS, 316SS pumps

Photo: R Welke 1974

Photo: R Welke 1974

Site testing a vertical turbine pump, USQ. Photo: R Welke

Economic Analysis

TRAINING

Tallemenco also offers an ADVANCED PUMPING AND HYDRAULICS Online training course. This course covers aspects of how to test pumps on site, how to measure electrical power and how to interpret results.

For more information on this training course, contact Tallemenco.

Tallemenco also offers an ADVANCED PUMPING AND HYDRAULICS Online training course. This course covers aspects of how to test pumps on site, how to measure electrical power and how to interpret results.

For more information on this training course, contact Tallemenco.

EXPERT WITNESS

Because of Rob's extensive pump testing experience on water pumps up to 5,000 kW, plus extensive flow meter R&D experience, Tallemenco is able to act in the capacity of Expert Witness for any client who needs an expert opinion on pump performance.

Many large pumping installations are poorly equipped with flowmetering, or no flowmeter at all. Since pump performance measuring accuracy is 90% dependent upon flow measurement accuracy, Tallemenco can provide the necessary expertise for a reliable pump test result, along with a critical assessment of pump testing measurement tolerances, essential to expert witness proceedings.

Because of Rob's extensive pump testing experience on water pumps up to 5,000 kW, plus extensive flow meter R&D experience, Tallemenco is able to act in the capacity of Expert Witness for any client who needs an expert opinion on pump performance.

Many large pumping installations are poorly equipped with flowmetering, or no flowmeter at all. Since pump performance measuring accuracy is 90% dependent upon flow measurement accuracy, Tallemenco can provide the necessary expertise for a reliable pump test result, along with a critical assessment of pump testing measurement tolerances, essential to expert witness proceedings.

Flow measurement plays a very important part of accurate pump testing results. Here, Rob checks pumped flows on a 900mm diameter discharge pipe using a portable velocity meter, with a Water Compliance Officer looking on.

Photo: Jeremy Cape.

Photo: Jeremy Cape.

Velocity meter on 900mm diameter pipe

Photo: R Welke

Photo: R Welke

ABN 92 105 345 506

Site commissioning 675/825 TKL Horiz Single Stage Cent 5,670 kW pumps, Murray Bridge Onkaparinga Pumping Station, SA Water. 1974

Photo: R Welke

Photo: R Welke

Tallemenco Pty Ltd, Windsor Gardens, SOUTH AUSTRALIA, 5087.

ABN: 92 105 345 506

Mobile 0414 492 256

Intn'l: Cell +61 414 492 256

Skype: robwelke

ABN: 92 105 345 506

Mobile 0414 492 256

Intn'l: Cell +61 414 492 256

Skype: robwelke

Last Update

Nov 8th 2019

Nov 8th 2019