“Pumping and Hydraulics’ Solutions for Irrigation and Water Supply”

ABN: 92 105 345 506

PUMPING ENERGY EFFICIENCY Auditing

Firstly, up until the mid 2000's, electricity was cheap and there was no demand for energy efficient irrigation pumping system design.

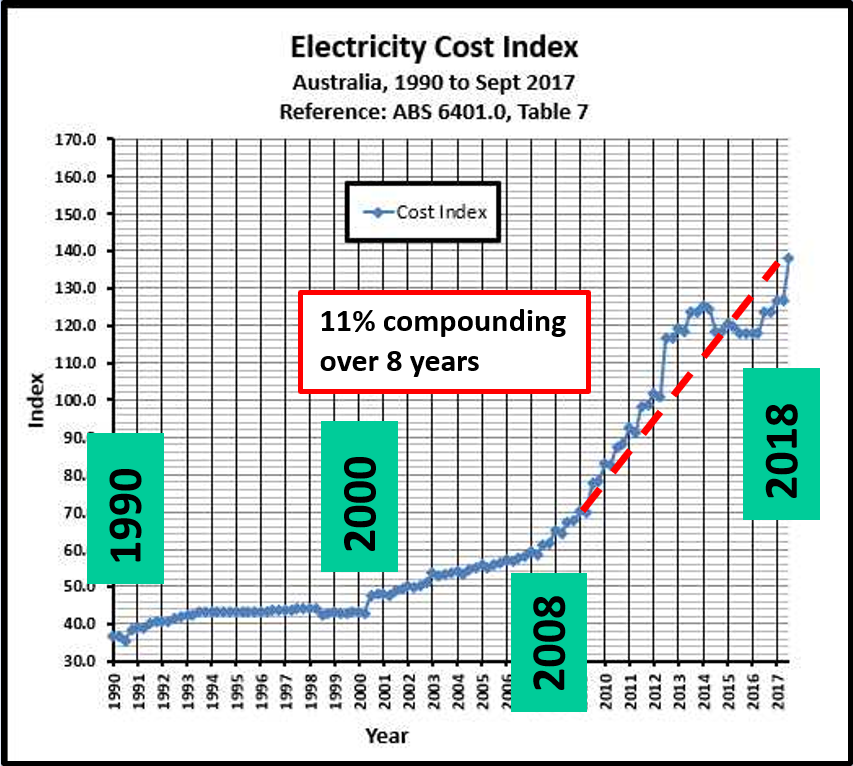

The chart, right, shows that the average Australian electricity cost was quite low until the year 2000, then climbed steadily, but since 2008, has risen dramatically. So, the exorbitant cost of electricity is now driving irrigators to despair with high operating costs.

Secondly, irrigation designs of the past have concentrated on water efficiency, but because of the low electricity costs of the past, energy efficiency has not been considered.

Therefore, it is almost guaranteed that there will be energy efficiency savings to be made on almost any existing pumped irrigation system from that era.

The chart, right, shows that the average Australian electricity cost was quite low until the year 2000, then climbed steadily, but since 2008, has risen dramatically. So, the exorbitant cost of electricity is now driving irrigators to despair with high operating costs.

Secondly, irrigation designs of the past have concentrated on water efficiency, but because of the low electricity costs of the past, energy efficiency has not been considered.

Therefore, it is almost guaranteed that there will be energy efficiency savings to be made on almost any existing pumped irrigation system from that era.

Energy Audit your own irrigation pumping system.

You can conduct your own energy efficiency audit on your own irrigation system. So, what do you look for?

Unfortunately, that cant be answered without being on site. However, you can learn for yourself what to look for and how to conduct your own audit.

Tallemenco, with over 50 years of energy efficiency experience in the water industry, has designed a training course to assist irrigation engineers, operators, managers and designers to assess their own irrigation systems for energy efficiency.

For more information,

go to "Pumping System Master Class" training.

You can conduct your own energy efficiency audit on your own irrigation system. So, what do you look for?

Unfortunately, that cant be answered without being on site. However, you can learn for yourself what to look for and how to conduct your own audit.

Tallemenco, with over 50 years of energy efficiency experience in the water industry, has designed a training course to assist irrigation engineers, operators, managers and designers to assess their own irrigation systems for energy efficiency.

For more information,

go to "Pumping System Master Class" training.

The cost of electricity in Australia has risen sharply in the last decade. This has made pumping energy efficiency audits justified and desirable for irrigators. Data from ABS, 6040.1 Table 7

Graph, R Welke

Graph, R Welke

How much will a pumping energy efficiency audit save?

That depends on many factors. Installations which have high head pumps and small diameter pipes to save on upfront costs will benefit the most.

Audits which Tallemenco has conducted over the last 4 years have identified achievable savings from 15% up to 50% of annual electricity costs.

However, there is almost always a cost to implement an energy saving, such as extra pipe, pump replacement or impeller trimming, etc, to potentiate those savings. Determining if energy savings are practical depends on reviewing the cost of implementing the savings vs the value of those savings (ROI).

That depends on many factors. Installations which have high head pumps and small diameter pipes to save on upfront costs will benefit the most.

Audits which Tallemenco has conducted over the last 4 years have identified achievable savings from 15% up to 50% of annual electricity costs.

However, there is almost always a cost to implement an energy saving, such as extra pipe, pump replacement or impeller trimming, etc, to potentiate those savings. Determining if energy savings are practical depends on reviewing the cost of implementing the savings vs the value of those savings (ROI).

Return on Investment (ROI)

Generally, costs associated with achieving energy savings are evaluated as a ratio of savings. For example, it may cost $30,000 upgrading pumps/pipes to save $10,000 in annual electricity.

That is usually expressed as a Return on Investment (ROI), which in the above example is a ROI of 3. That's equivalent to investing money into your own business with a 33% return!

However, with the rise in electricity costs being much higher than CPI, it would be reasonable to capatilise those savings, thus achieving an actual higher ROI.

Tallemenco has designed software to readily analyse costs savings and ROI for clients.

Generally, costs associated with achieving energy savings are evaluated as a ratio of savings. For example, it may cost $30,000 upgrading pumps/pipes to save $10,000 in annual electricity.

That is usually expressed as a Return on Investment (ROI), which in the above example is a ROI of 3. That's equivalent to investing money into your own business with a 33% return!

However, with the rise in electricity costs being much higher than CPI, it would be reasonable to capatilise those savings, thus achieving an actual higher ROI.

Tallemenco has designed software to readily analyse costs savings and ROI for clients.

An energy efficiency audit on this hydroponic lettuce farm identified annual energy savings of 50% by replacing the pumps and applying some hydraulic optimisation. ROI was 2.2 yrs.

Refer story HERE. Photo, R Welke

Refer story HERE. Photo, R Welke

Energy savings on this pumping system were created through hydraulic optimisation and were potentiated by trimming the impeller to lower operating head.

Refer story HERE Photo, R Welke

Refer story HERE Photo, R Welke

Contact Rob for a quote to conduct a pumping energy efficiency audit to save operating costs on your irrigation system.

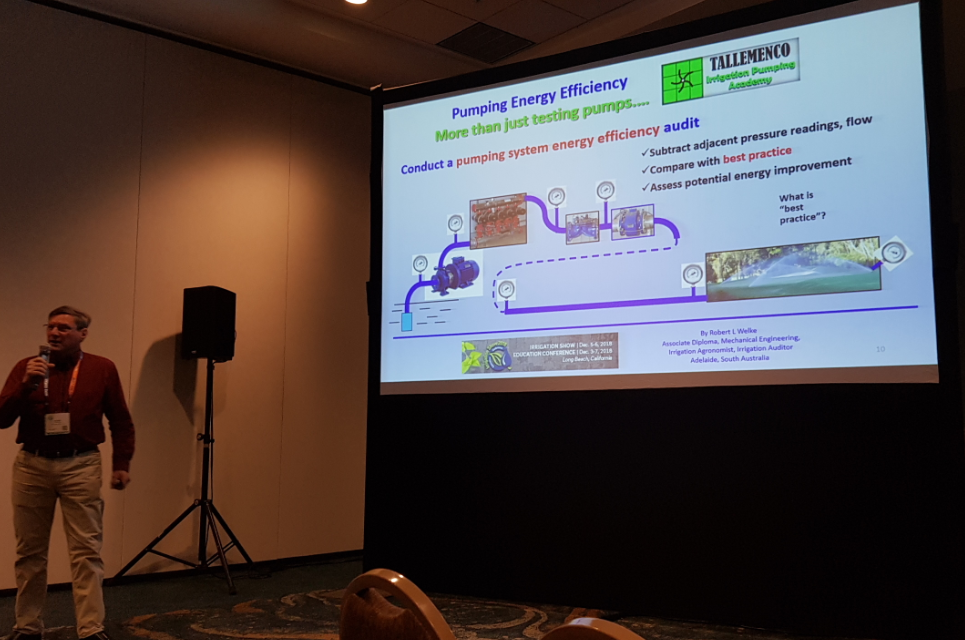

Tallemenco runs Face 2 Face and ONLINE training courses to assist operators to conduct their own energy efficiency audits. Here, Rob is conducting a training session in Long Beach California at the 2018 IA Conference.

Tallemenco Pty Ltd, Windsor Gardens, SOUTH AUSTRALIA, 5087.

ABN: 92 105 345 506

Mobile 0414 492 256

International: Cell +61 414 492 256

ABN: 92 105 345 506

Mobile 0414 492 256

International: Cell +61 414 492 256

Why have pumping energy efficiency audits?

Last Updated

May 18th, 2020

May 18th, 2020

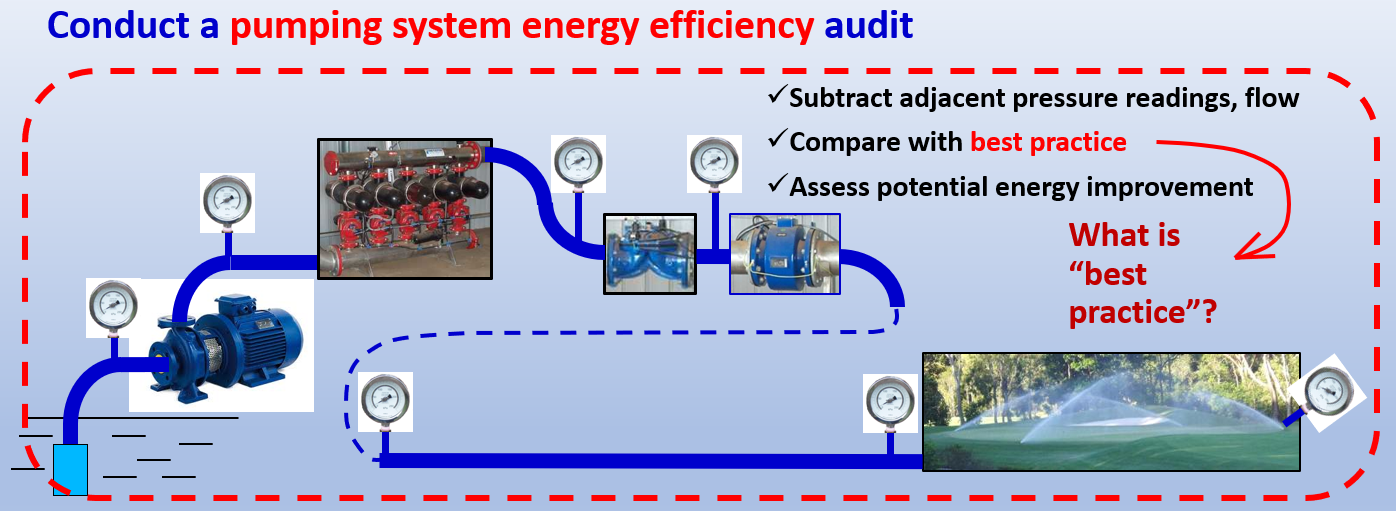

Holistic approach to pumping audits

However, pumping energy efficiency is more than just about testing pumps. Pumping energy efficiency involves every part of the irrigation system that has a head loss, eg pipes and fittings.

This is covered in more detail in our ENERGY FACT SHEET 01

Tallemenco takes a holistic approach to pumping energy efficiency auditing and audits both the pumps and the pipelines, and all fittings in between. Auditing pipelines (and fittings) is otherwise known as an hydraulic energy efficiency audit.

In fact, in all of Tallemenco's pumping energy audits, hydraulic efficiency has yielded the most savings.

That can best be illustrated with the following diagram:

(Note the broken red limit line around ALL irrigation components)

However, pumping energy efficiency is more than just about testing pumps. Pumping energy efficiency involves every part of the irrigation system that has a head loss, eg pipes and fittings.

This is covered in more detail in our ENERGY FACT SHEET 01

Tallemenco takes a holistic approach to pumping energy efficiency auditing and audits both the pumps and the pipelines, and all fittings in between. Auditing pipelines (and fittings) is otherwise known as an hydraulic energy efficiency audit.

In fact, in all of Tallemenco's pumping energy audits, hydraulic efficiency has yielded the most savings.

That can best be illustrated with the following diagram:

(Note the broken red limit line around ALL irrigation components)

Audits to AS 3598 2014 Type 2

If you want to take advantage of Govt funding, you will be required to undertake a detailed energy efficiency audit to AS 3598 Type 2. This standard requires ALL farm site energy consumptions to be analysed and examined for savings, including diesel, LPG etc.

Because there are rigid additional auditing requirements and high compliance, over and above just a pumping energy efficiency audit, Govt funded audits will be 25% to 50% more costly than a straight pumping energy efficiency audit.

The sensible approach is to get Tallemenco to do an IPEEAT audit on your system first to determine if a detailed audit to AS 3598 Type 2 is going to yield sufficient energy efficiency savings in your pumping system to make it worthwhile!

Read more about IPEEAT here...

If you want to take advantage of Govt funding, you will be required to undertake a detailed energy efficiency audit to AS 3598 Type 2. This standard requires ALL farm site energy consumptions to be analysed and examined for savings, including diesel, LPG etc.

Because there are rigid additional auditing requirements and high compliance, over and above just a pumping energy efficiency audit, Govt funded audits will be 25% to 50% more costly than a straight pumping energy efficiency audit.

The sensible approach is to get Tallemenco to do an IPEEAT audit on your system first to determine if a detailed audit to AS 3598 Type 2 is going to yield sufficient energy efficiency savings in your pumping system to make it worthwhile!

Read more about IPEEAT here...

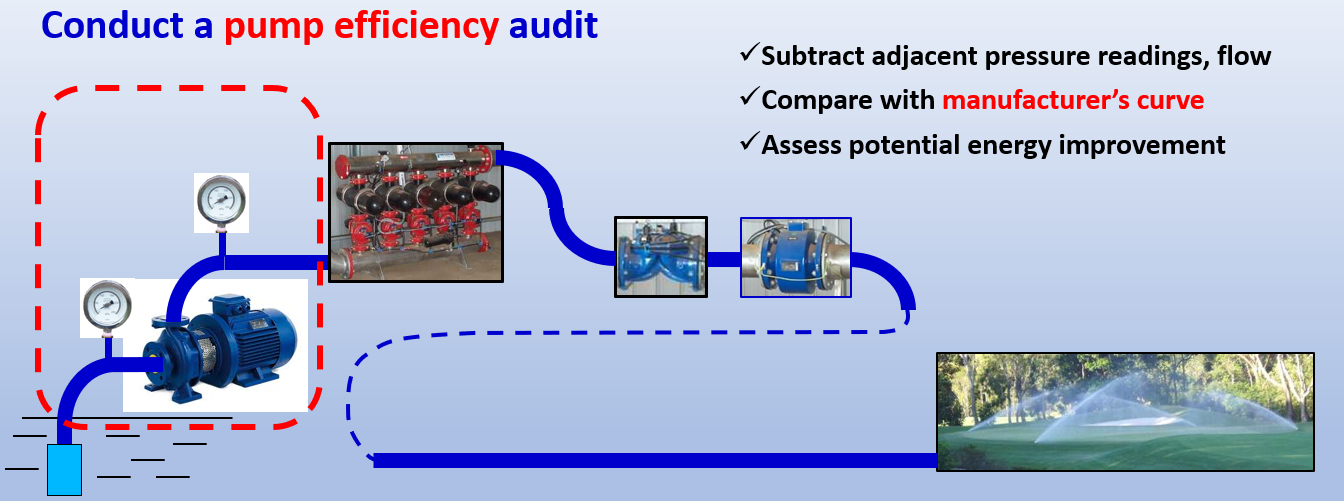

What is a pump energy efficiency audit?

All auditors in the Australian irrigation industry will audit ONLY the pumps to test for pumping energy efficiency. Why? Because that is what the irrigation industry trains them to do.

That can best be illustrated with the following diagram:

Note the broken red limit line around the pump.

All auditors in the Australian irrigation industry will audit ONLY the pumps to test for pumping energy efficiency. Why? Because that is what the irrigation industry trains them to do.

That can best be illustrated with the following diagram:

Note the broken red limit line around the pump.