“Pumping and Hydraulics’ Solutions for Irrigation and Water Supply”

Flow Metering

During the 1980’s and 1990’s, Rob assisted in the technical responsibility for over 2500 irrigation flow meters for SA Water’s Water Resources Diversions from the River Murray.

As part of that responsibility, he conducted numerous accuracy investigations on a variety of irrigation flowmeters up to 300mm as well as potable water flow meters, such as turbine, positive displacement and ultra-sonics.

As part of that responsibility, he conducted numerous accuracy investigations on a variety of irrigation flowmeters up to 300mm as well as potable water flow meters, such as turbine, positive displacement and ultra-sonics.

To ensure the flow meters’ accuracy, Rob conducted extensive accuracy testing using a test rig with NATA certified master flow meter to determine accuracy parameters for these and other potable water flow meters.

In addition, during the same time period, Rob conducted extensive on-site flowmeter calibrations for master flowmeters and pump station pump testing flowmeters for SA Water’s potable water distribution system.

In addition, during the same time period, Rob conducted extensive on-site flowmeter calibrations for master flowmeters and pump station pump testing flowmeters for SA Water’s potable water distribution system.

Evaluating flow meter accuracy. Photo, R Welke

As a result, Rob has an extensive knowledge base of many issues with flow meter accuracy for mechanical, clamp-on ultrasonic and magnetic flow meters.

For example, Robs' very first field test on a flowmeter was in 1971 on a 68" NB (1.73m) magnetic flowmeter, fully imported from UK and installed on the Happy Valley, SA, reservoir outlet on 2 km of straight pipe.

A volumetric test was conducted into a 2 million gallon (10ML) tank. The flowmeter was 30% slow! Obviously this flowmeter was not tested before leaving the factory! This was in the early days of magnetic flowmeters and there has been enormous headway in technology since then.

However, this was also one of many experiences Rob had over the years of manufacturers releasing flowmeter product into the market place without fully testing, leaving him with a somewhat cautious respect for flowmeter manufacturers' accuracy claims.

For example, Robs' very first field test on a flowmeter was in 1971 on a 68" NB (1.73m) magnetic flowmeter, fully imported from UK and installed on the Happy Valley, SA, reservoir outlet on 2 km of straight pipe.

A volumetric test was conducted into a 2 million gallon (10ML) tank. The flowmeter was 30% slow! Obviously this flowmeter was not tested before leaving the factory! This was in the early days of magnetic flowmeters and there has been enormous headway in technology since then.

However, this was also one of many experiences Rob had over the years of manufacturers releasing flowmeter product into the market place without fully testing, leaving him with a somewhat cautious respect for flowmeter manufacturers' accuracy claims.

Rob uses his flowmeter knowledge for pump station designs and flow meter retro-fits to ensure installation will result in accuracy of flow measurement.

Also, for pump testing, knowledge of flow meter accuracy limits is extremely important in establishing reliable pump test results.

The H-Q accuracy of pump tests is determined 90% by flowmeter accuracy and 10% by pressure measurement, the latter being much more predictable. Velocity meters such as one shown below can be used to accurately measure flow.

Also, for pump testing, knowledge of flow meter accuracy limits is extremely important in establishing reliable pump test results.

The H-Q accuracy of pump tests is determined 90% by flowmeter accuracy and 10% by pressure measurement, the latter being much more predictable. Velocity meters such as one shown below can be used to accurately measure flow.

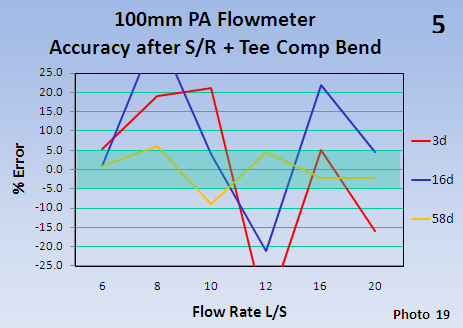

Graph of flow meter accuracy test. Graph, R Welke

In Robs experience, there is widespread misunderstanding of flowmetering accuracy expectations.

As a result, he has prepared a 56 page Technical presentation, "Flowmeters - How much straight pipe?" to dispel the popular myth that all flowmeters require 10 diameters of upstream straight pipe, and 5 diameters of downstream straight pipework. The presentation covers the following meter types:

As a result, he has prepared a 56 page Technical presentation, "Flowmeters - How much straight pipe?" to dispel the popular myth that all flowmeters require 10 diameters of upstream straight pipe, and 5 diameters of downstream straight pipework. The presentation covers the following meter types:

| ■ | Propeller Actuated (Inferential) |

| ■ | Turbines |

| ■ | Tangential Paddlewheels |

| ■ | Multijet |

| ■ | Insertion (4 types covered) |

| ■ | Magnetic |

| ■ | Ultrasonic |

| ■ | Use of straightening vanes |

TRAINING

The Flowmetering presentation is part of Tallemenco's

Advanced Pumping & Hydraulics and

Pumping System Master Class

training courses.

Contact Rob for more details.

The Flowmetering presentation is part of Tallemenco's

Advanced Pumping & Hydraulics and

Pumping System Master Class

training courses.

Contact Rob for more details.

Here, a portable velocity meter is being used to measure pumped flow on a 900mm diameter discharge pipe. Flow measurement plays a very important part of accurate pump testing results.

Photo: Rob Welke.

Photo: Rob Welke.

ABN 92 105 345 506

Last Update

Nov 8th 2019

Nov 8th 2019

Tallemenco Pty Ltd, Windsor Gardens, SOUTH AUSTRALIA, 5087.

ABN: 92 105 345 506

Mobile 0414 492 256

Intn'l: Cell +61 414 492 256

Skype: robwelke

ABN: 92 105 345 506

Mobile 0414 492 256

Intn'l: Cell +61 414 492 256

Skype: robwelke